Integrated Part Finishing Service

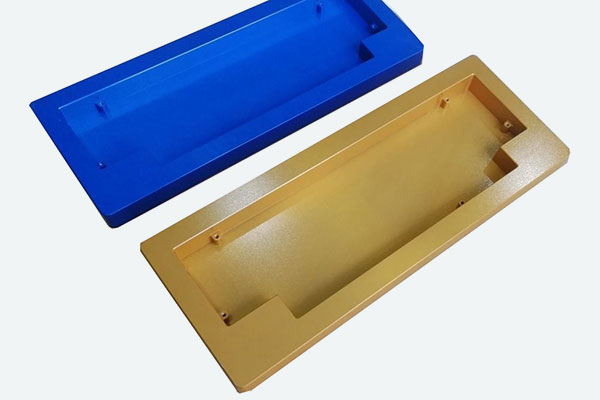

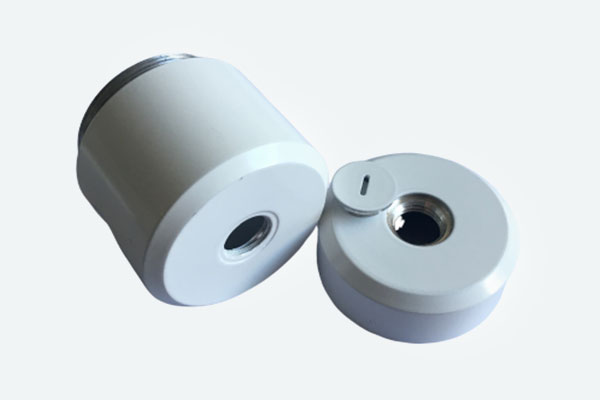

Whether it is CNC machined, sheet metal parts, or 3D printing parts, to gain an accurate appearance of your final product, before leaving our factory many products may undergo a series of finishing services for beautiful appearance or functional benefit.

Finishing services improve resistance to corrosion, improve the visual appearance, protect against wear, and offer a host of additional benefits.

SinoRise provides an integrated part finishing service to meet your diverse needs.

With our experienced in-house skills and advanced facilities, we try our best to ensure the color, texture, gloss, and surface finish of parts and exceed your expectations.