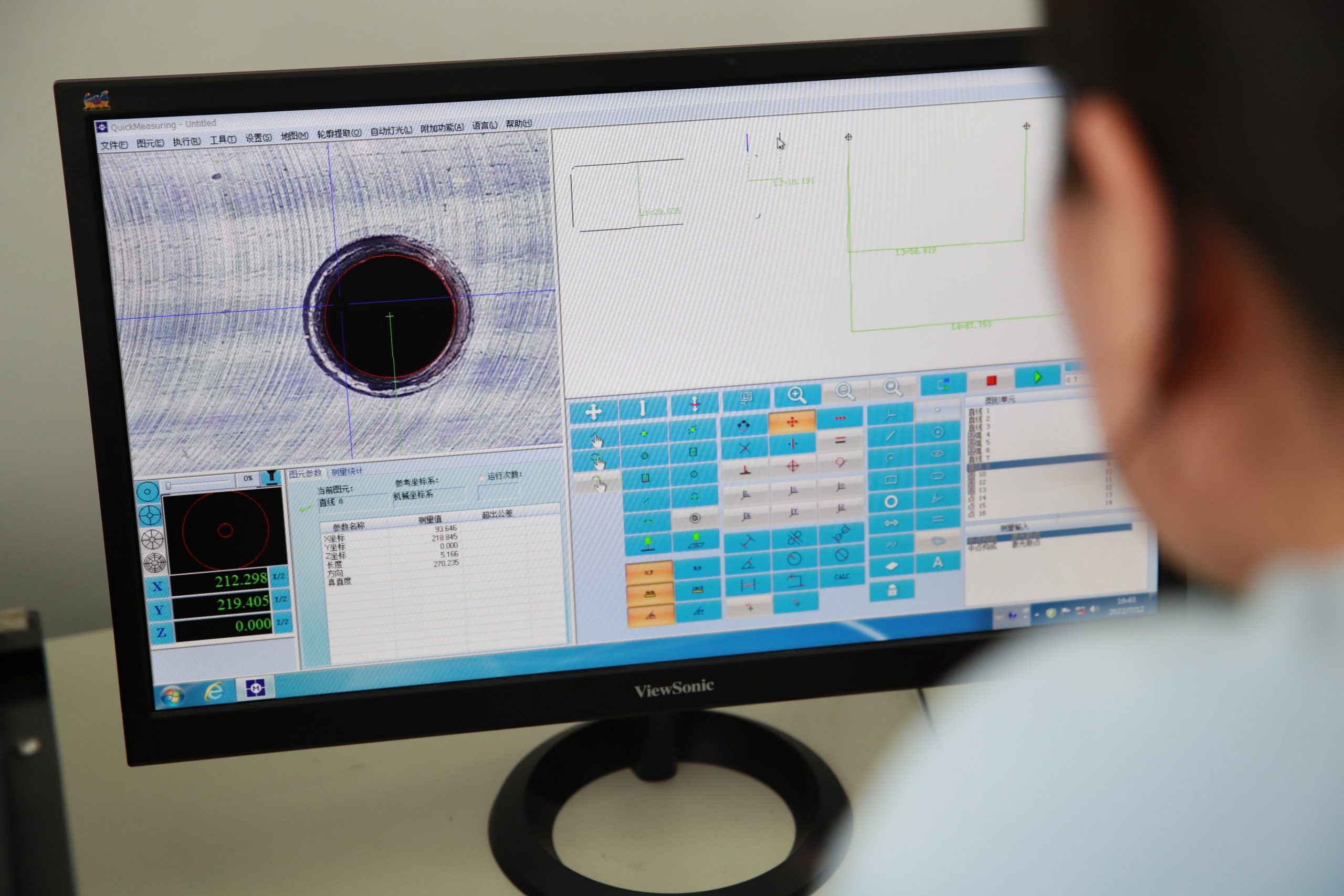

Industrial design prototyping can be seen as a bridge between the initial concept design stage and the production stage of manufacturing. Prototyping will progress iteratively in conjunction with product design to ensure that the development process continues to perform as designed and intended.

Prototyping Will Bring Your Designs To Life

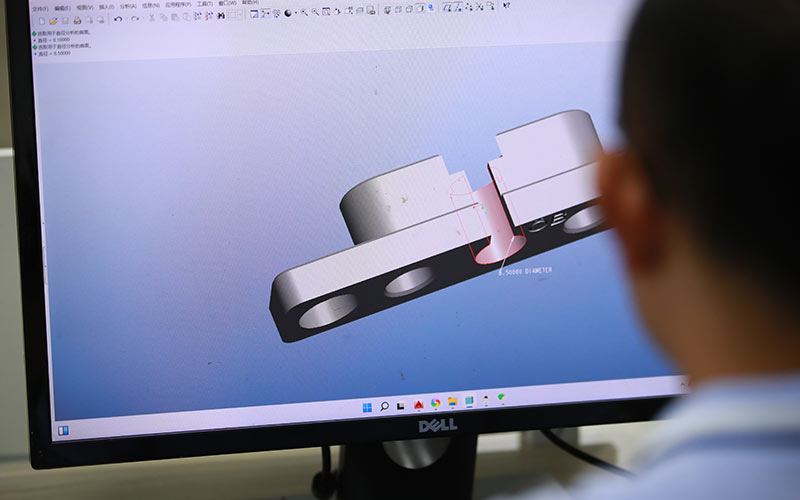

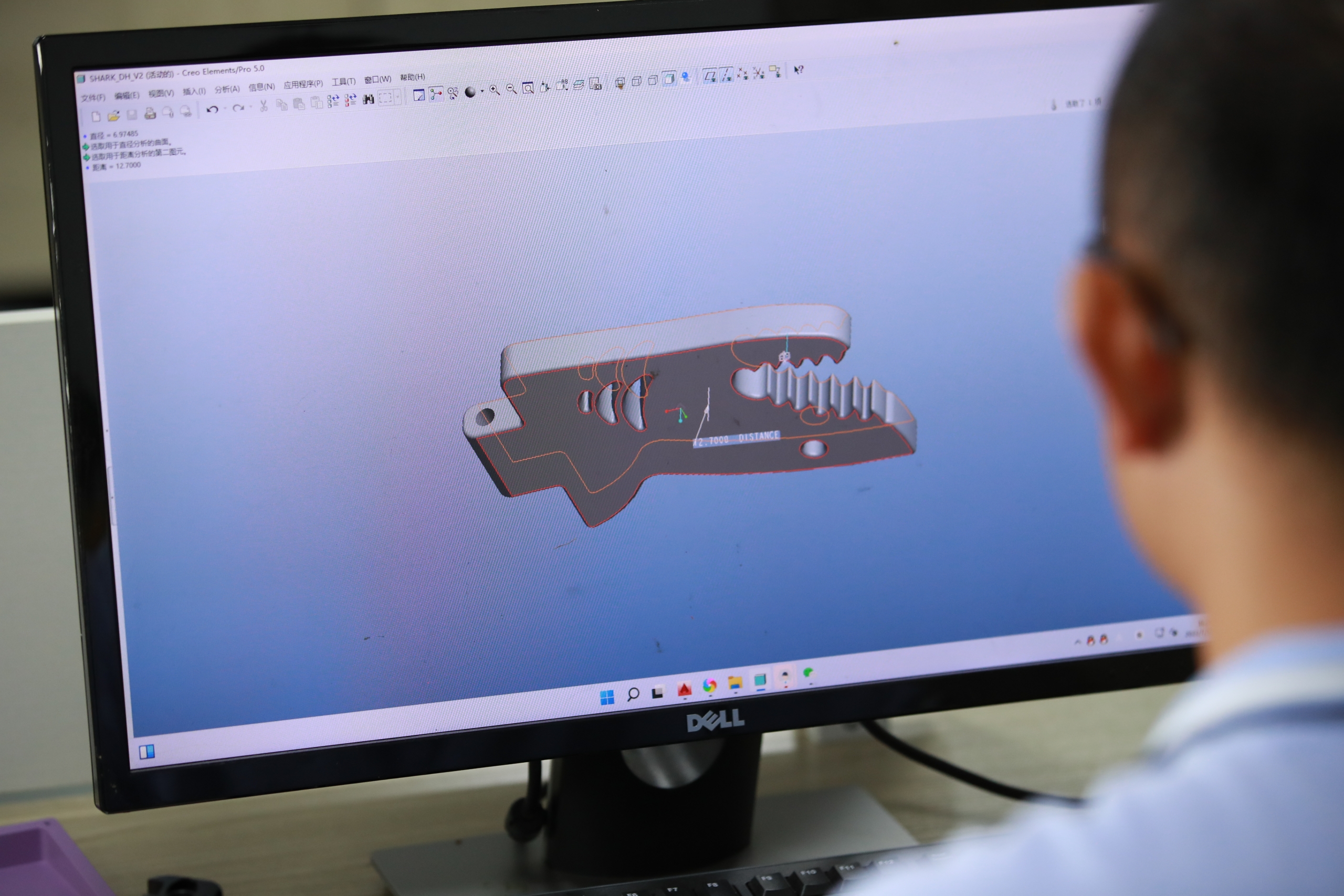

From the initial concept prototype and visual presentation models to

complex design functional prototypes, as well as challenging precision

machined parts, we are able to support at all levels.